Enkambweni ye-transformer winding, ngenxa yezizathu ezihlukahlukene, kulula ukubangela ukuwela phansi kwesendlalelo.

Ngakho-ke, izoholela ini isendlalelo se-transformer winding drop drop? Ingabe izoqhuma? Ngalesi sigameko, singakugwema kanjani?

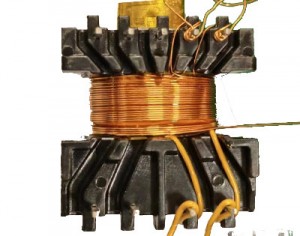

Esihlokweni esithi "Ulwazi lokuphepha lwe-transformer", siyazi ukubaluleka kwebanga le-creepage kanye nebanga likagesi. Ukuze uhlangabezane nemfuneko yebanga, sengeza i-tape kanye ne-casing insulation ku-transformer; phakathi kwesisekelo sokuqala nesesibili, sisebenzisa futhi udonga olubambayo kanye nocingo oluvalekile lwezendlalelo ezintathu ukuze sihlangabezane nemfuneko.

Uma i-transformer ilahle izendlalelo, khona-ke i-creepage kanye namabanga kagesi phakathi kwama-windings ngeke ahlangane. I-Transformer windings ingase ibe nkulu kakhulu ngenxa yomehluko wengcindezi phakathi kwama-windings, futhi ukusondela kwesizathu, kulula ukuholela ekuqhekekeni kwe-short-circuit, ukuze ukukhishwa kwe-transformer okungavamile, kungakwazi ukusebenza kahle, noma kubangele ngokuqondile i-transformer ishile.

Ngisho noma i-transformer ingabonakali ingavamile isikhathi esifushane, izophinde ibe nomthelela empilweni ye-transformer. Ngokungangabazeki, umehluko wengcindezi mkhulu kakhulu, eduze nokuvunguza, umsebenzi wesikhathi eside uzosheshisa ukuguga kwezinto zokufakelwa kwe-transformer, ngaleyo ndlela kuthinte impilo ye-transformer yonke.

Ngakho-ke, ohlelweni lokuklama i-transformer kanye nokujika, ungakugwema kanjani ukulahla izendlalelo?

Okokuqala, ngenxa yokuvuthwa kwangaphakathi kwe-transformer, kufanele uzame ukwenza yonke i-design layer.Idizayini eminingi ye-transformer, ngokuvamile ngokusebenzisa izibalo zethiyori zonjiniyela bamandla, ngaphandle kokusonteka kwangempela, isampula yokukhiqiza kwayo isilingo ngokuvamile inikezwa ifektri ye-transformer enesibopho.

Ngenxa yokuchezuka kwesibalo setiyori kanye nokujikajika kwangempela, kulula ukuvela wonke umugqa wesendlalelo unganelisekile. Ngalesi sikhathi, ngenxa yokuthi i-bottom of the winding ayiyona flat, wonke umugqa wesendlalelo awunelisekile ngesimo, ingemuva le-winding elijikayo kuyoba lula ukuwela ngaphandle kwesendlalelo.

Ngakho-ke, ekwakhiweni kwe-transformer, ekuklanyeni kwangaphakathi kwamawindi, zama ukucabangela yonke i-design layer. Ngoba ngempela abakwazi ukuhlangabezana nesimo, kodwa futhi eduze lonke ungqimba design. Kunjalo, lonke ungqimba lomklamo kufanele lilawulwe lifinyelele emaphethelweni afanele, lingaxegi kakhulu noma lingaqini kakhulu, ukuze kuqinisekiswe ukuthi imishini ehlukene ephuma ephaketheni, iyisendlalelo esiphelele noma izendlalelo eziningi.

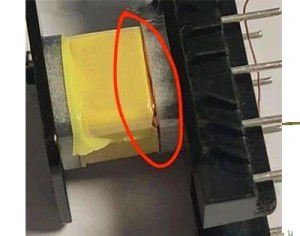

Okwesibili, esimweni sezinye ze-windings azikho inani elikhulu lokuphenduka, ngisho nokuvunguza nakho kulula ukuholela ekunciphiseni ungqimba.Lesi simo sikhona hhayi kuphela ezingomakhelwane windings yangaphakathi kungukuthi ahlelwe endabeni yonke ungqimba, kodwa futhi likhona angomakhelwane yangaphakathi mazombezombe wire ububanzi ushubile, emaphethelweni iningi indilinga kanye skeleton kukhona ngokuvamile igebe elikhulu phakathi icala.

Ngalesi sikhathi, uma izidingo zokuklama ngisho nokuvunguza, unqenqema lwendilinga kanye nohlaka lwamathambo ludinga ukushiya ibanga elithile phakathi, ukuze kuvinjwe ngokuphelele ngisho nokugoqa kwecala, emshinini ngaphansi kwesenzo sokungezwani, ingaphandle langaphandle. ukusonga konqenqema oluningi lwe-1 ~ 2 kuphenduka ngqo ekujikeni kwangaphakathi konqenqema lwegebe, okuholela ekuwa kongqimba.

Ngaphezu kwalokho, ukuchema iphakethe tape emazombezombe, tape lincane kakhulu, futhi kulula ukuholela nesenzakalo of ungqimba falling. Ngakho-ke, inqubo yokuguqula i-transformer ibaluleke kakhulu.

Kuyafaneleka ukubalula: enqubweni yokukhiqiza ngobuningi, i-transformer winding winding, ngokuvamile imishini ezenzakalelayo noma e-semi-automatic, esheshayo, eshiya ungqimba olumazombezombe akulula ukutholakala. Ngenxa yalokhu, kuvame ukuba nzima kakhulu ukuqapha ukuphuma kwe-transformer winding.

Ngaphezu kokuqinisekisa ubuhlakani bomklamo, inqubo yokusonta yephakeji yomugqa, qaphela ukuhlakazeka kwephakheji, bheka ukuvumelana kwephakheji, hlola ukuthi ngabe kwenzeka yini ukwehla kwezingqimba.

Isikhathi sokuthumela: Sep-21-2024